Chapter 1 Industry Development Overview

1.1 definition

Industrial 4.0 (Industry 4.0) represents the future of manufacturing. It marks the arrival of the fourth industrial revolution by integrating advanced digital technologies into production and industrial processes. This concept covers a wide range of technologies, including the Industrial Internet of Things (IIoT), artificial intelligence (AI), big data, robotics, and automation, with the aim of enabling smart manufacturing and creating smart factories. Through industrial 4.0, enterprises can improve production efficiency, flexibility, and realize intelligent decision-making and customization of production process and supply chain operation.

Industrial 4.0 is reshaping the way businesses design, manufacture and distribute products. Technologies such as the Industrial Internet of Things (IIoT), cloud computing, artificial intelligence and machine learning are now deep into the entire manufacturing process, and the deep integration of these technologies has brought unprecedented connectivity and intelligence to manufacturing. In this new manufacturing mode, products, factories and assets can be interconnected and intelligent, thus greatly improving production efficiency and product quality, while reducing production costs.

Industrial 4.0 is not only a technological innovation, it also represents a new way of working and thinking. Enterprises need to adapt to this change and adopt more flexible and adaptive production methods to cope with the rapid changes in market demand. By implementing intelligent production processes, companies can achieve greater production flexibility and shorter time-to-market, while also being able to provide more personalized products and services.

1.2 development process

Industrial 4.0, also known as the Fourth Industrial Revolution (4IR), is based on the division of different stages of industrial development, marking the intelligent era of using information technology to promote industrial change. The development of this concept is based on the first three industrial revolutions, each of which profoundly changed the mode of production and social structure.

The first industrial revolution began in England at the end of the 18th century, marking the transition from manual labor to mechanized production. Through the use of water and steam power, mass production became possible, and machines replaced traditional human and animal power. The finished products of this period were mainly manufactured by machine rather than by hand.

Immediately afterwards, the second industrial revolution arrived a century later, introducing assembly line production methods, and oil and electricity began to be widely used. The application of new energy sources, combined with advanced means of communication such as telephone and telegraph, has brought about the initial realization of larger-scale production and automation for the manufacturing industry.

The third industrial revolution occurred in the middle of the 20th century, with the introduction of computers, advanced communication technologies and data analysis, and the digitization of manufacturing processes. The use of programmable logic controllers (PLCs) makes it possible to automate some processes, while also facilitating the collection and sharing of data.

We are now in the fourth industrial revolution, the era of industrial 4.0, the core of which is to increase production efficiency through automation and intelligent equipment, and use data-driven decision-making to achieve more efficient and effective goods production throughout the value chain. This period is characterized by an increase in production flexibility, enabling manufacturers to better meet customer needs through mass customization, achieving efficiency and scale integration. Smart factories achieve information transparency and better decision-making by collecting shop floor data and combining it with enterprise operation data.

The concept of industrial 4.0 was first proposed at the Hannover Messe in Germany in 2013 to improve the competitiveness of German industry. The German government has listed it as one of the top ten future projects in the "German 2020 High Technology Strategy", with an estimated investment of 0.2 billion billion euros to promote the intelligentization of the manufacturing industry and the establishment of resource-efficient and adaptable smart factories. The technical basis of industrial 4.0 is the network entity system (Cyber-Physical Systems, CPS) and the Internet of Things. Through these technologies, the supply, manufacturing, and sales information in production is digitized and intelligent to achieve fast, effective and personalized product supply.

Germany's "Industrial 4.0" strategy emphasizes the transition from centralized control to decentralized enhanced control, and aims to establish a highly flexible personalized and digital production model. Under this model, traditional industry boundaries will disappear, new areas of activity and forms of cooperation will be generated, the division of labor in the industrial chain will be reorganized, and the manufacturing industry will be transformed to intelligence by making full use of information and communication technology and cyberspace virtual systems.

Industrial 4.0 is not only a technological revolution, it also represents a profound change in the mode of production, the organization of enterprises and the whole social structure. With the continuous advancement of information technology and intelligent manufacturing, industrial 4.0 will continue to lead the global manufacturing industry towards a more efficient and intelligent future.

1.3 development status

The current state of China's industrial 4.0 is built on breakthrough technologies such as the Internet of Things, cloud computing, artificial intelligence, virtual reality, value-added manufacturing, and robotics. This development strategy aims to build a "smart factory" with high flexibility and high resource utilization by fully integrating and optimizing resources, talents and information in the virtual and real worlds ". Industrial 4.0 creates a "digital thread" that runs through the entire business value chain by enabling continuous, real-time flow of information from product development, procurement, manufacturing, distribution, retail to the end customer ". This not only greatly improves the transparency of information, but also achieves a significant reduction in operating costs, a high degree of product personalization, flexible and efficient manufacturing and product development processes, and also promotes business model innovation.

Although China has written a manufacturing legend in the past 30 years, its productivity level still lags far behind that of developed countries. In the past, the rapid growth of China's manufacturing industry mainly relied on cheap labor, capital and imitation of innovation. However, with the gradual disappearance of these competitive advantages, China is facing the pressure of transformation and upgrading. Therefore, the Chinese government issued the "Made in China 2025" policy, which aims to use the wave of industrial 4.0 to promote China's transformation from the world's largest manufacturing country to a developed manufacturing country.

In order to successfully achieve digital transformation, Chinese manufacturers must find a digital transformation path suitable for Chinese characteristics based on their own status quo. This includes strengthening R & D investment in core technology fields, improving innovation capabilities, optimizing industrial structure, and cultivating highly skilled talents. At the same time, strengthening exchanges and cooperation with international advanced manufacturing industries, absorbing and learning from international advanced technology and management experience are also important ways to achieve transformation and upgrading.

Chapter 2 Industry Chain, Business Model, and Policy Regulation

2.1 industry chain

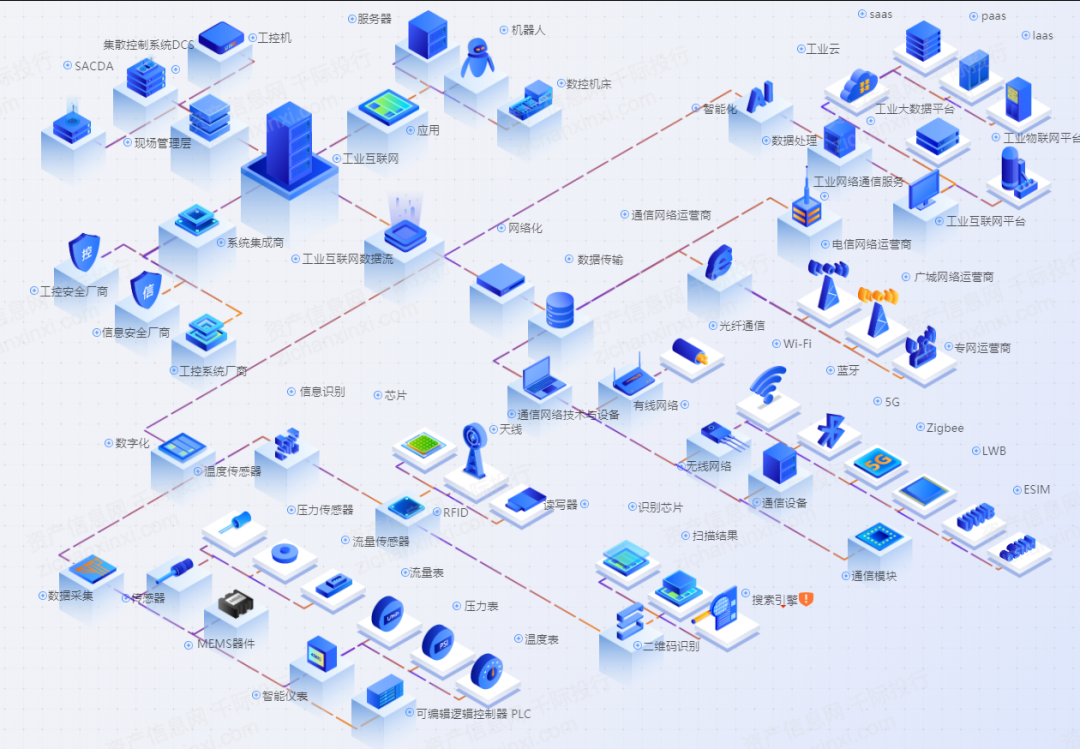

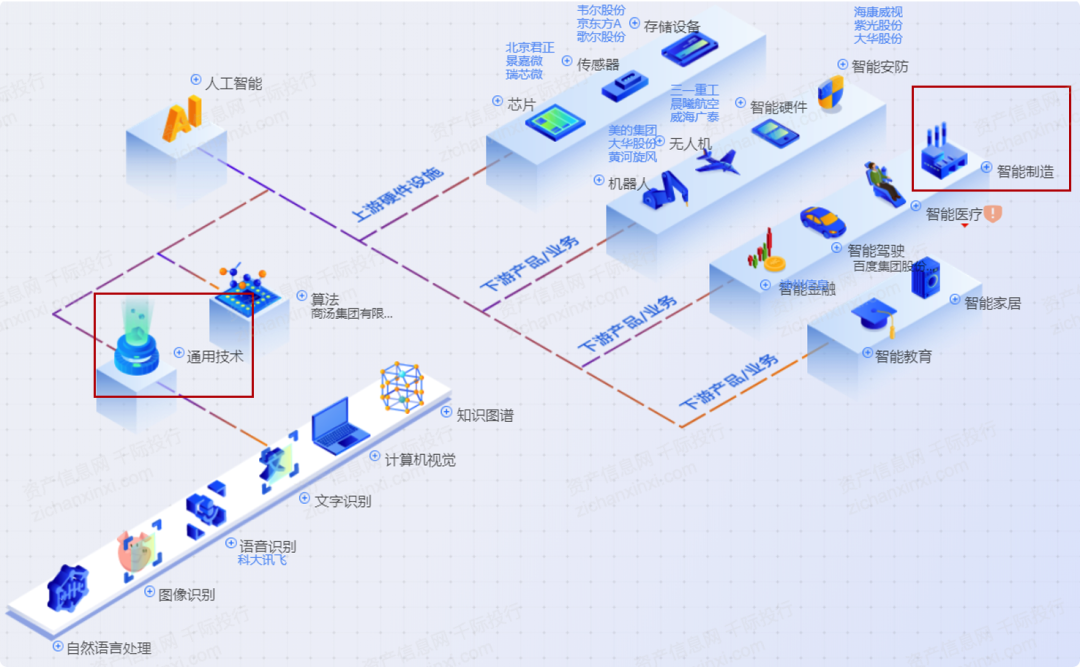

industrial 4.0 involves many industrial chains such as industrial internet and intelligent manufacturing.

Figure Industrial Internet and Artificial Intelligence Industry Chain

Source: Asset Information Network Qianji Investment Bank iFinD

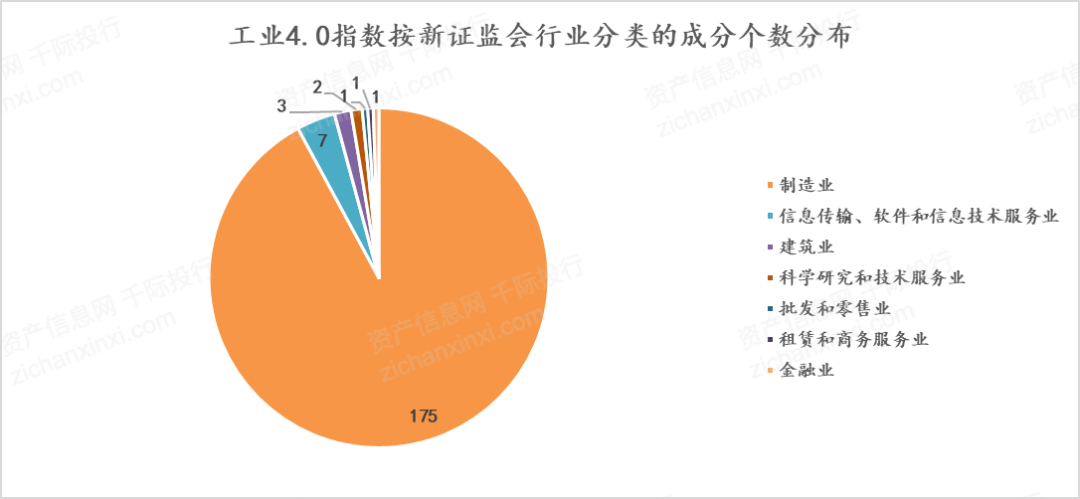

iFinD data show that the largest number of components in the industrial 4.0 index is manufacturing, with 129 components.

Figure Distribution of the number of components of the Industrial 4.0 Index by new SEC industry classification

Source: Asset Information Network Qianji Investment Bank iFinD

2.2 business model

In the era of industrial 4.0, the business model of China's manufacturing industry is undergoing a major transformation. This transformation focuses on solving customer problems, not only focusing on hardware sales, but also maximizing value by providing value-added services and personalized solutions. This shift reflects the evolution from traditional manufacturing to "soft manufacturing" plus customization, in which information systems become the core of products and services. The following is an analysis of China's industrial 4.0 business model.

Characteristics of smart factories

Smart factories use embedded sensors and machine connectivity to make optimal decisions based not only on internal data, but also on external data from suppliers and distributors to provide deeper insights into production and operations. The application of digital twin technology, I .e. the creation of digital representations of operations, further improves the accuracy and efficiency of decision-making.

The integration of IT and operational technology (OT) ensures the real-time flow and sharing of data, enabling information interconnection between ERP and other business management software, and providing technical support for customized production and supply chain management.

Custom Production

Another distinctive feature of the industrial 4.0 era is the ability to economically and effectively meet the individual needs of customers, that is, to achieve "mass customization". Through advanced simulation software, new materials and technologies such as 3D printing, manufacturers can produce small batches of customized products for specific customers, which is in sharp contrast to the mass production of the first industrial revolution.

Supply Chain Optimization

Transparency and efficiency in the supply chain are key to achieving an industrial 4.0 strategy. Through data sharing, manufacturers can work closely with suppliers to optimize material procurement and product delivery, reduce costs and improve responsiveness. The application of blockchain technology provides new possibilities for supply chain management, making supply chain transparency, security and traceability significantly improved.

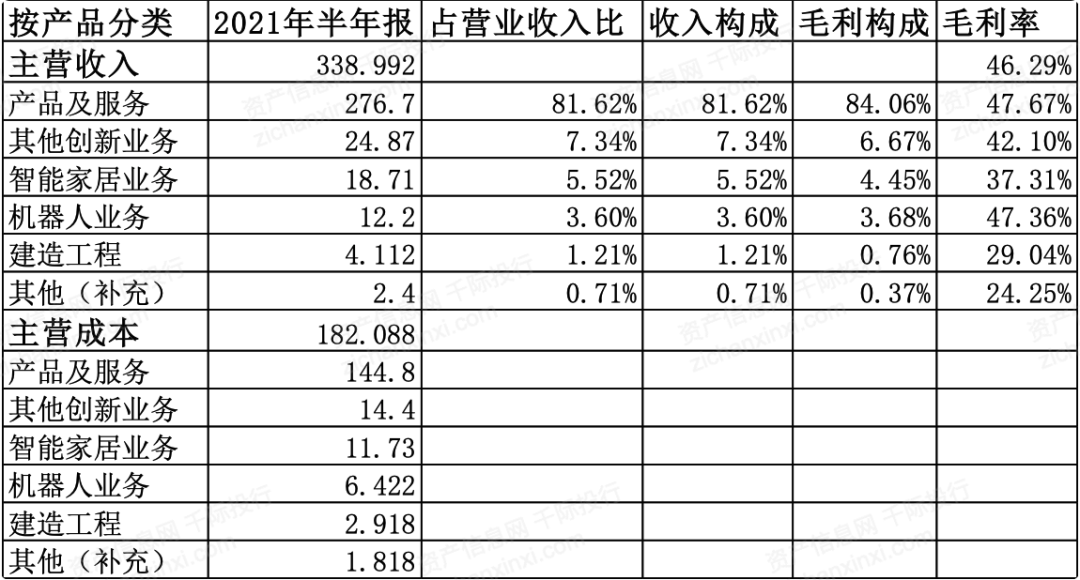

Revenue Cost Analysis

In the context of industrial 4.0, the revenue model of manufacturing companies has also changed, no longer relying solely on product sales, but by providing comprehensive solutions and services to increase added value. For example, through after-sales services, data analytics services and customized solutions, companies can get a continuous revenue stream. At the same time, measures such as smart factories and supply chain optimization can help reduce production and operating costs and improve the overall profitability of enterprises.

Table Midea Group (000333.SZ) Revenue Cost Analysis (billion yuan)

Source: Asset Information Network Qianji Investment Bank Dongfang Fortune

Table Hikvision (002415.SZ) Revenue Cost Analysis (RMB 100 million)

Source: Asset Information Network Qianji Investment Bank Dongfang Fortune

Table Haier Zhijia (600690.SH) Revenue Cost Analysis (Billion Yuan)

Source: Asset Information Network Qianji Investment Bank Dongfang Fortune

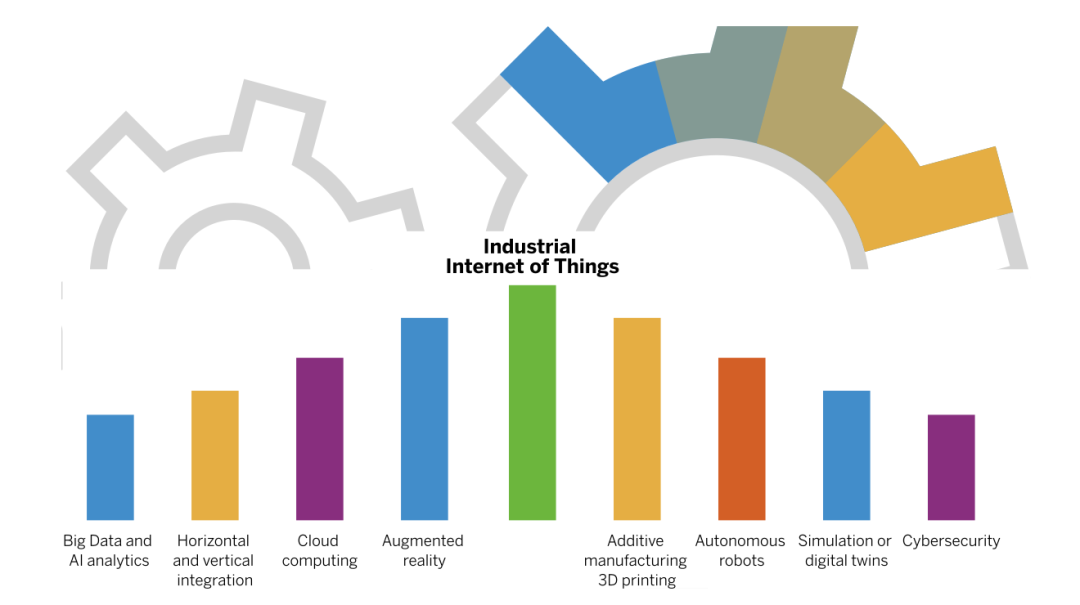

2.3 technology development

Industrial 4.0 marks the arrival of the fourth industrial revolution, the core of which is to use advanced information technology to promote the intelligent transformation of manufacturing industry. This revolutionary development is based on nine technological pillars that together bridge the physical and digital worlds, opening the way for intelligent autonomous systems.

Big data and AI analytics are one of the cornerstones of industrial 4.0. In this framework, big data not only comes from internal assets and equipment, but also includes external market trends and customer feedback. The analysis and application of these data greatly promotes the intelligence and automation of decision-making. The application of artificial intelligence (AI) and machine learning makes it possible to extract valuable insights from this vast amount of data to optimize manufacturing processes and supply chain management.

Horizontal and vertical integration technologies enable efficient synergy of production processes and organizational structures. Horizontal integration realizes the seamless connection of the production process by connecting different production links and supply chain links. Vertical integration ensures a smooth flow of information from the production site to top management, helping to break down information silos and improve the operational efficiency of the entire organization.

Cloud computing technology provides powerful data processing and storage capabilities for industrial 4.0, supporting real-time analysis of large amounts of data and global resource sharing. The application of cloud technology not only accelerates the pace of innovation, but also enables enterprises to respond flexibly to market changes.

Augmented reality (AR) technology greatly improves work efficiency and accuracy by superimposing digital information in the real world. Whether it is assembly guidance on the production line or fault diagnosis in the maintenance process, AR technology has shown great application potential.

The Industrial Internet of Things (IIoT) connects equipment, robots, machinery and other entities to the Internet to collect and analyze data in real time, optimize production processes, and predict maintenance needs, so as to realize highly intelligent and automated production processes.

Additive manufacturing and 3D printing technology provide the possibility of customized production and rapid prototyping by transforming digital models into physical objects, while also providing new ideas for reducing inventory and production costs.

The development of autonomous robots has further advanced production automation. These robots can perform complex operational tasks, reduce labor requirements, and improve production efficiency and safety.

Simulation and digital twin technology enables enterprises to test and optimize production processes in a risk-free environment by creating virtual copies of entities, accelerating product development cycles and reducing research and development costs.

The importance of network security in industrial 4.0 is self-evident. As more and more devices are connected to the Internet, protecting enterprises from cyber attacks and data breaches becomes particularly critical.

The above nine technical pillars together constitute the foundation of industrial 4.0. Their comprehensive application has not only changed the mode of production, but also reshaped the competitive landscape of the global manufacturing industry. With the continuous development and maturity of these technologies, it is expected that the future industrial 4.0 will bring more intelligent, flexible and personalized production solutions to inject new vitality into the global economic growth.

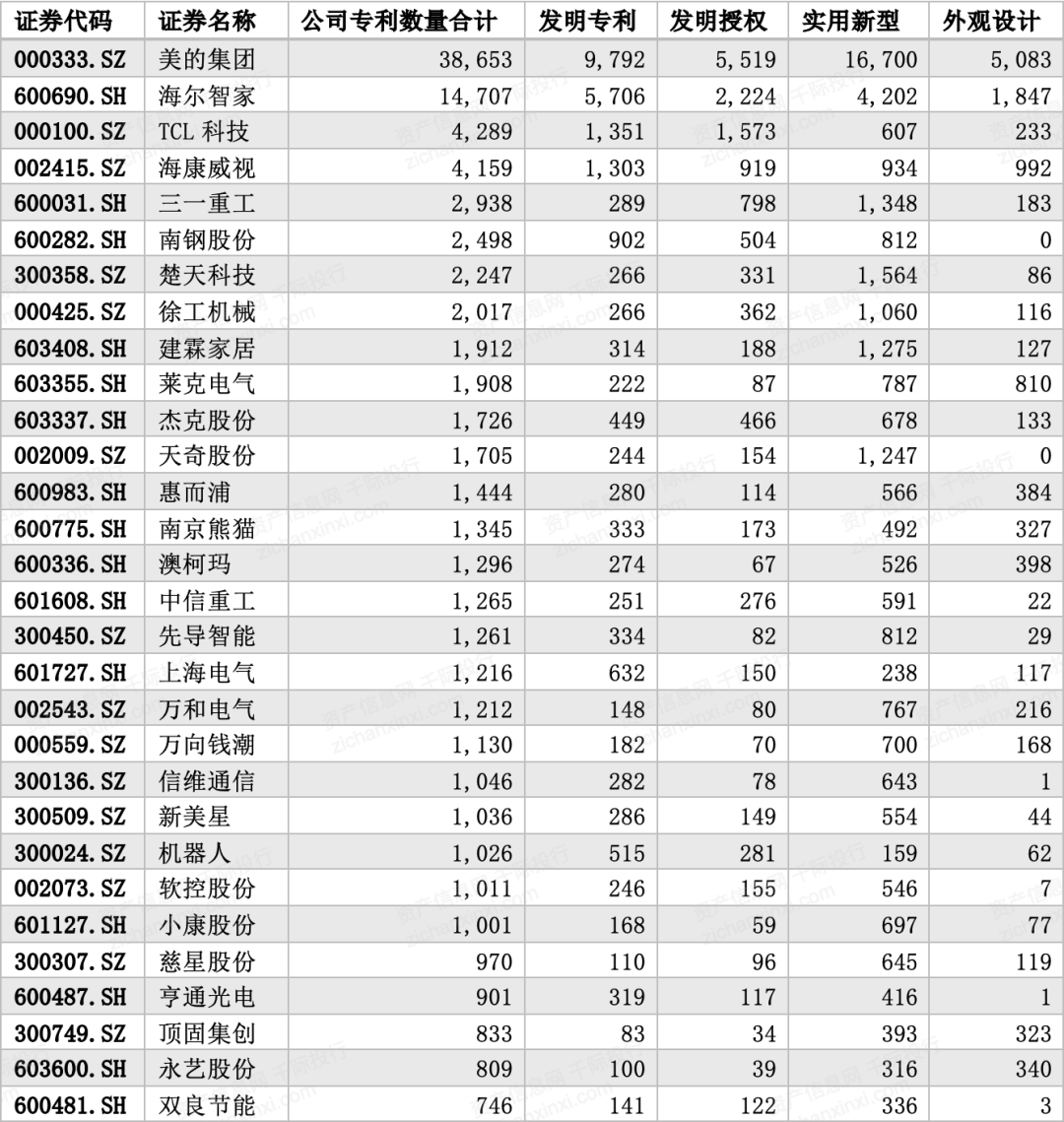

iFinD data shows that there are 190 listed companies in the industrial 4.0 sector. Among them, the top three companies in the number of patents granted are Midea Group, Haier Zhijia and TCL Technology, with 38653, 14707 and 4289 patents granted respectively.

the number of patents of listed companies in the table industrial 4.0 sector TOP30

Source: Asset Information Network Qianji Investment Bank iFinD

2.4 policy regulation

In China, the development and supervision of industrial 4.0 involves many government departments and industry organizations, reflecting the country's high attention to promoting the fourth industrial revolution and intelligent manufacturing. Together, these departments and organizations form a complex regulatory system aimed at promoting the healthy development of industrial 4.0 and ensuring that technological innovation and industrial upgrading go hand in hand.

Specifically, the industrial 4.0 industry is regulated by the Development and Reform Commission (NDRC), the Ministry of Science and Technology (Ministry of Science and Technology), the Ministry of Industry and Information Technology (Ministry of Industry and Information Technology), the Ministry of Justice, the Ministry of Finance, the State-owned assets Supervision and Administration Commission of the State Council (SASAC), the State Administration of Market Supervision and Administration, the State intellectual property Office, the State Standardization Administration of quality Supervision and Inspection and Quarantine. These departments are responsible for formulating relevant policies, supervising implementation, promoting technological innovation, protecting intellectual property rights, formulating standards, etc., and jointly promote the healthy and orderly development of industrial 4.0.

In addition to government departments, China also has industry self-regulatory organizations such as China Construction Machinery Industry Association, China Industrial Design Association, China Electrical Equipment Industry Association, China Automobile Industry Association, and independent research institutions such as Industrial 4.0 Research Institute. They are promoting The fourth industrial revolution played an important role in industry-university-research cooperation, technological innovation and strategic planning. As an independent research institution facing the fourth industrial revolution, the Institute of Industrial 4.0 not only focuses on the research of technology, patents, strategies, models and practices, but also promotes innovation through in-depth cooperation with universities, research institutions and industrial enterprises. The formation and development of ecology.

At the policy level, the Chinese government has issued the "Intelligent Manufacturing Development Plan (2016-2020)", the "13th Five-Year" National Strategic Emerging Industry Development Plan, and the "Intelligent Hardware Industry Innovation and Development Special Action (2016-2018)" and a series of policy documents aimed at promoting the development of intelligent manufacturing and industrial 4.0. As an important document guiding the medium and long-term development of China's manufacturing industry, "Made in China 2025" clarifies the roadmap of intelligent manufacturing, emphasizing innovation-driven, quality improvement, green development, structural optimization and talent-oriented development strategies.

Chapter 3 Financial, Risk, and Competitive Analysis

3.1 Financial Analysis and Valuation Methods

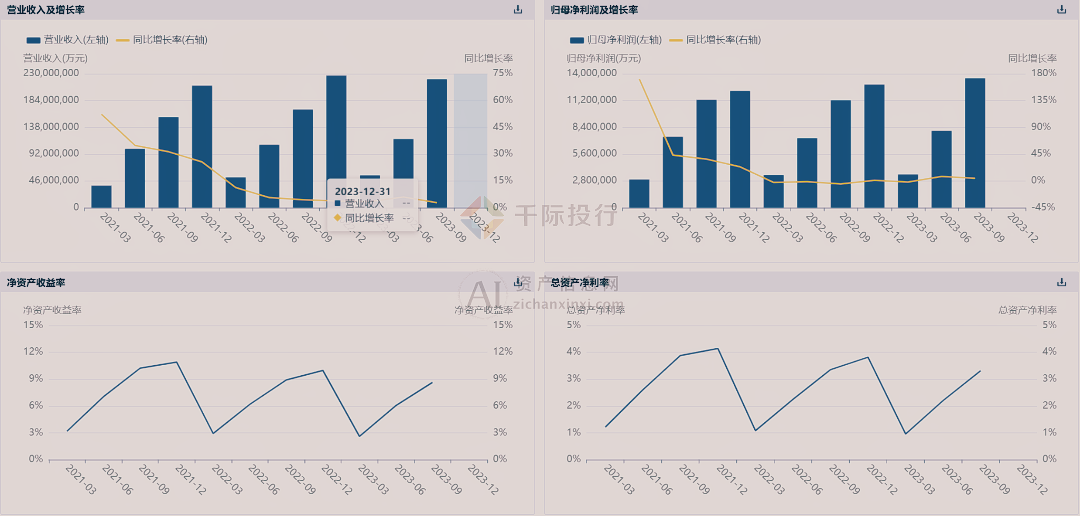

Chart Industrial 4.0 Index 885619.TI Financial Data

Source: Asset Information Network Qianji Investment Bank iFinD

Figure Industrial 4.0 Index Market Performance

Source: Asset Information Network Qianji Investment Bank iFinD

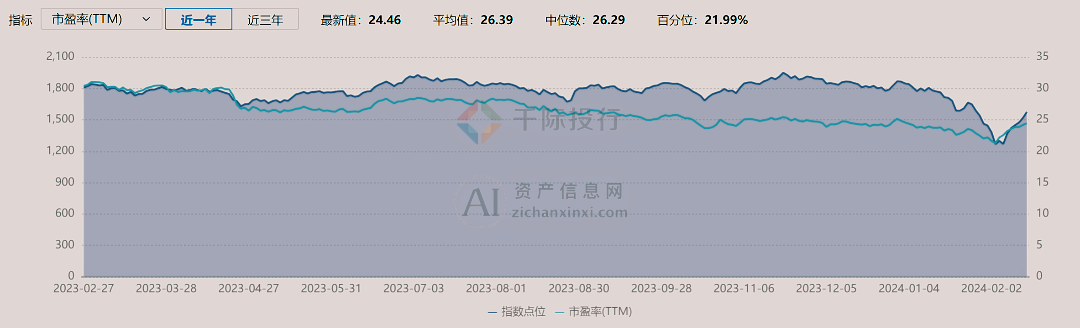

Chart Industrial 4.0 Index P/E

Source: Asset Information Network Qianji Investment Bank iFinD

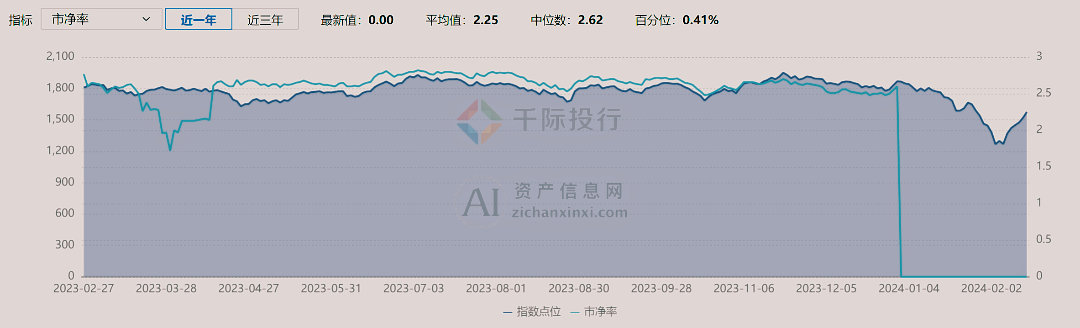

Figure Industrial 4.0 Index Price-to-Book Ratio

Source: Asset Information Network Qianji Investment Bank iFinD

Figure TOP10 Value Comparison of Industrial 4.0 Index Components

Source: Asset Information Network Qianji Investment Bank iFinD

Figure Flush ESG Ranking TOP10

Source: Asset Information Network Qianji Investment Bank iFinD

the valuation methods of industrial 4.0 constituent stocks can be selected from price-earnings ratio valuation method, PEG valuation method, price-to-book ratio valuation method, market-to-market ratio, P/S market-to-sales ratio valuation method, EV / Sales market-to-market ratio valuation method, RNAV revaluation net assets valuation method, EV/EBITDA valuation method, DDM valuation method, DCF cash flow discount valuation method, NAV net assets valuation method, etc.

3.2 drivers

The development of China's industrial 4.0 is driven by a variety of factors, which together constitute the driving force for the transformation of China's manufacturing industry to a higher level and more intelligent direction. This article will explore the main factors driving the development of China's industrial 4.0.

First of all, policy support is one of the key factors to promote the development of industrial 4.0. The Chinese government attaches great importance to the transformation and upgrading of the manufacturing industry, and has provided clear guidance and strong support for the development of the industrial 4.0 through a series of policy documents such as the "Made in China 2025. These policies aim to accelerate the construction of intelligent manufacturing systems and intelligent production lines through technological innovation, quality improvement, and green development, and improve the overall competitiveness of the manufacturing industry.

Secondly, technological progress is another important factor driving industrial 4.0. With the rapid development of information technology, big data, cloud computing, artificial intelligence and other technologies, it provides a strong technical foundation for industrial 4.0. In particular, technological breakthroughs in the fields of the Internet of Things, intelligent manufacturing, and digital twins have greatly promoted the transformation of production methods, enabling the manufacturing industry to achieve more efficient, more flexible production models and smarter decision-making.

Furthermore, changes in market demand are also an important driving force for the development of industrial 4.0. With globalization and market competition intensifying, customers' demand for personalized products is growing, which requires the manufacturing industry to provide more flexible and fast customized services. Through intelligent production processes, industrial 4.0 can effectively respond to this change in market demand and realize the transformation from large-scale standardized production to customized and personalized production.

In addition, the demand for industrial upgrading is also an important factor in promoting the development of industrial 4.0. Facing the challenges of slowing economic growth and rising labor costs, China's manufacturing industry urgently needs to optimize and upgrade its industrial structure through technological innovation and model innovation. By introducing intelligent technology and equipment, industrial 4.0 can not only improve production efficiency and product quality, but also promote the development of emerging industries and promote the adjustment and optimization of economic structure.

Finally, international cooperation has also provided impetus for the development of China's industrial 4.0. Through cooperation with international advanced enterprises and research institutions, China can not only introduce advanced technology and management experience, but also participate in the high-end links of the global value chain and enhance its international competitiveness.

We believe that policy support, technological progress, changes in market demand, the need for industrial upgrading, and international cooperation have jointly promoted the development of China's industrial 4.0. In the future, with the continuous effect of these factors, China's industrial 4.0 will achieve wider application and deeper development, injecting new impetus into the transformation and upgrading and sustainable development of China's manufacturing industry.

3.3 Risk Analysis

With the rapid development of China's industrial 4.0, facing the huge opportunities brought by technological innovation and industrial transformation, it is also accompanied by a series of risks and challenges. This paper will analyze the main risks that may be faced in the development of China's industrial 4.0.

First, technical safety risk is an important consideration in the development of industrial 4.0. With the wide application of Internet of things, big data, cloud computing and artificial intelligence, data security and privacy protection have become urgent problems to be solved. While enjoying the convenience and efficiency improvement brought by these technologies, enterprises are also faced with the risks of data theft, system hacking, privacy leakage and so on, which not only threatens the security of enterprises themselves, but also may affect the security of the whole industry and even the country.

Secondly, the risk of industrial restructuring can not be ignored. The advancement of industrial 4.0 will prompt major adjustments in the industrial structure. Some traditional industries and positions may be eliminated, and new industries and occupations will appear. In this process, how to balance the transformation of old and new industries and ensure the smooth transfer of labor is a challenge that the government and society need to face together.

Furthermore, there is a risk of a shortage of skilled personnel. The development of industrial 4.0 is highly dependent on technological innovation and talent support. At present, China still has a talent gap in some high-end technology fields, especially in cutting-edge technology fields such as big data, cloud computing, and artificial intelligence. The training and introduction of technical talents has become one of the bottlenecks restricting the development of industrial 4.0.

In addition, the risk of international competition is also an issue that China's industrial 4.0 needs to face up. With the further development of globalization, international competition is becoming more and more fierce. On the one hand, China needs to face strong competition from developed countries in the field of high-end manufacturing; on the other hand, it also needs to pay attention to the competition of emerging market countries in cost control and market expansion. How to maintain an advantage in international competition is a key issue that needs to be addressed in the process of China's industrial 4.0 development.

Finally, standardization and interoperability risks. Industrial 4.0 involves the application and integration of many new technologies, and standardization and interoperability between different devices and systems become the key. The lack of uniform standards and protocols may lead to waste of resources, reduced efficiency, and even affect the stability and security of the entire production system.

Qianji Investment Bank believes that although the development of China's industrial 4.0 has broad prospects, it also faces risks in many aspects, such as technical security, industrial structure adjustment, shortage of technical personnel, international competition, standardization and interoperability. To deal with these risks, we need the joint efforts of the government, enterprises and all sectors of society to ensure the healthy, stable and sustainable development of the industrial 4.0 by strengthening technological research and development, optimizing the industrial structure, training high-end talents, strengthening international cooperation and formulating unified standards.

3.4 competition analysis

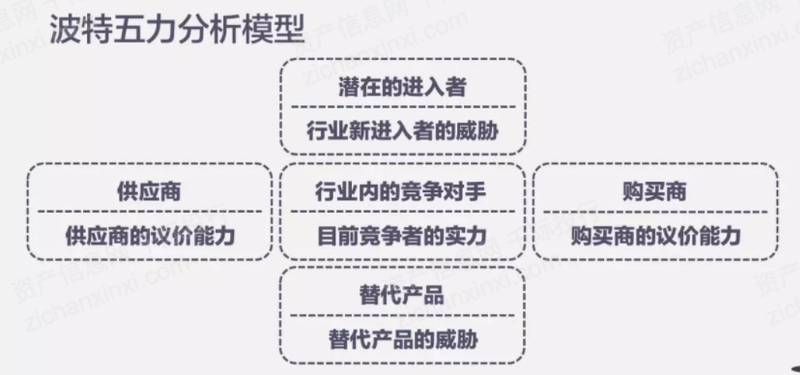

Porter's Five Forces Model is a framework proposed by Michael Porter to analyze the competitive situation of the industry. The model evaluates the competitive intensity and profitability of the industry by analyzing five forces-competitors in the industry, potential new entrants, threats of substitutes, bargaining power of suppliers and bargaining power of buyers. In the context of China's industrial 4.0, we can use Porter's five forces model to analyze its competitive situation.

Source: Qianji Investment Bank Asset Information Network iFinD

Competitors in the industry

China's industrial 4.0 market is highly competitive, with many companies competing in the fields of intelligent manufacturing, automation technology, and information technology. With the continuous advancement of technology and the expansion of application scenarios, the competition among enterprises has changed from a single product and service competition to a comprehensive strength competition, including technological innovation capabilities, market response speed, and customized service capabilities.

Potential new entrants

The Chinese government's strong support for industrial 4.0 and the huge potential demand in the market have attracted many new entrants. These new entrants include start-ups, multinational companies, and transformational companies in other industries. They bring new vitality to the market through investment in capital, technology, and innovation models, while also intensifying industry competition.

Threat of substitutes

With the iterative update of technology, new technologies and solutions are constantly emerging, and the threat of alternatives is gradually increasing. For example, the development of cloud computing, big data and other technologies provides enterprises with new production and management methods, which may pose an alternative threat to traditional industrial automation equipment and information systems.

Bargaining power of suppliers

In the field of industrial 4.0, high-quality raw materials, advanced production equipment and technical services are the key to production. Suppliers such as chip manufacturers and software providers occupy an important position in the market and have strong bargaining power. However, with the increase in market participants and the improvement of global supply chains, companies are also seeking to diversify their supply channels to reduce their dependence on a single supplier.

Bargaining power of buyers

As information transparency increases and market choices increase, the bargaining power of buyers (especially large manufacturing companies and groups) increases. They pay more attention to the cost performance of products and services, technical support and customized service capabilities, which requires suppliers to continuously improve their competitiveness to meet market demand.

We believe that the competitive situation of China's industrial 4.0 is characterized by fierce competition in the industry, frequent new entrants, increasing threat of substitutes, and changing bargaining power of suppliers and buyers. In such a market environment, enterprises need to constantly innovate and improve their own capabilities to cope with the complex and changeable competitive challenges.

3.5 important participating enterprises

Table Some Listed Companies in Industrial 4.0 Sector

Source: Asset Information Network Qianji Investment Bank iFinD

1/Midea Group (000333.SZ)

"science and technology is good, life is perfect"-midea group adheres to the business philosophy of creating a better life with science and technology. after 53 years of development, it has become a global science and technology group integrating smart home, building science and technology, industrial technology, robot and automation, and digital innovation. in the past five years, it has invested nearly 45 billion yuan in research and development (annual revenue accounts for more than 3.5 percent), with 28 R & D centers and 34 major production bases around the world, products and services benefit about 0.4 billion users in more than 200 countries and regions around the world.

2/Central Control Technology (688777.SH)

Zhejiang Zhongkong Technology Co., Ltd. was established in 1In 999, it is a high-tech enterprise and a national technological innovation demonstration enterprise. Always adhering to the mission of "making work and life easier", we are committed to providing intelligent manufacturing products and solutions with automation control system as the core, covering industrial software, automation instruments and operation and maintenance services for industrial enterprises dominated by process industry, so as to enable users to improve the level of automation, digitization and intelligence, and realize the automation, digitization and intelligent management of industrial production.

3/Hikvision (002415.SZ)

Hikvision is an intelligent Internet of Things solution and big data service provider with video as its core. Its business focuses on intelligent Internet of Things, big data services and intelligent services. It builds an open cooperation ecology, provides services for users in public service fields, enterprises and small and medium-sized enterprises, and is committed to building smart cities and digital enterprises with cloud-edge integration, material-trust integration and digital intelligence integration.

Chapter 4 Future Outlook

With the profound changes in the global economic environment and the accelerated pace of scientific and technological innovation, the development of China's industrial 4.0 is standing at a new historical starting point. Under the background of this era, the transformation and upgrading of China's manufacturing industry is not only an urgent need, but also an important opportunity for leapfrog development. Looking to the future, the trajectory of China's industrial 4.0 will be a multi-dimensional development process that integrates innovative technology, intelligent manufacturing, green development and international cooperation.

Technology innovation will continue to be the core driving force for the development of industrial 4.0. The in-depth application of cutting-edge technologies such as artificial intelligence, Internet of Things, big data and cloud computing indicates that the manufacturing industry will usher in a double improvement in production efficiency and product quality. The construction of smart factories, the application of digital twin technology and the popularization of customized production will become the new development direction of the manufacturing industry, enabling enterprises to respond more flexibly to market demand and provide personalized solutions.

At the same time, green sustainability will become an important dimension of industrial 4.0 development. Facing the common challenge of global environmental protection, Chinese industry will realize the greening of production process, reduce energy consumption and waste discharge through technological innovation, and promote the development of manufacturing industry in a more environmentally friendly and sustainable direction.

The integration and optimization of industrial ecology is also the key to the development of industrial 4.0 in the future. By building a closely coordinated industrial chain and supply chain and optimizing resource allocation, China's manufacturing industry will enhance its overall competitiveness and achieve a more efficient production and operation model.

In terms of international cooperation and open innovation, China will actively integrate into the global value chain, deepen cooperation with international advanced enterprises and research institutions through international cooperation platforms such as the "Belt and Road", promote technological exchanges and talent flow, and accelerate industrial 4.0 Globalization process.

Qianji Investment Bank believes that the challenges facing China's industrial 4.0 cannot be ignored, including the improvement of technological innovation capabilities, the training of highly skilled talents, and internal resistance to transformation and upgrading. China needs to build a more open, innovative and collaborative industrial system, and jointly promote China's industrial 4.0 towards a more intelligent, green and international future through policy support, education and training and international cooperation.

Author: Qianji Investment Bank

Cover: AI Generation

Ticker Name

Percentage Change

Inclusion Date