Wheeled Robots Gain Edge Over Bipedal Peers in China’s Factories

Wheeled Robots Gain Edge Over Bipedal Peers in China’s Factories(Yicai) Sept. 29 -- Chinese manufacturers prefer wheeled robots to bipedal humanoids for factory work because they are cheaper, more energy efficient, and can handle heavier loads, though some experts argue that two-legged robots could gain the upper hand if certain technical hurdles are overcome.

Manufacturers and robot producers have noticed over the past year that bipedal humanoids consume too much energy and cannot keep up with the pace of assembly line work, Liu Changwen, general manager of Shanghai-based industrial robot maker Step Electric, told Yicai.

“I personally feel that a consensus is forming, which is that two-legged humanoid robots are unsuitable for factories,” Liu said.

Bipedal robots use 40 percent of their energy and 60 percent of their computing power just to move their legs, yet this generates no value in a factory. Even humanoid robot makers are also now rolling out wheeled models in large numbers, Liu added.

Step Electric recently deployed a humanoid robot in white goods maker Haier’s refrigerator factory in Chongqing, with two goals in minds, Liu said. “The first is to upgrade robot control systems to meet real on-the-ground factory needs,” he said. “The second is to gather industrial data that will give us the data foundation to train the next generation of robots when we start mass production.”

Puzhi Robotics has shipped 200 robots, of which 60 percent are wheeled and 40 percent are legged, Cai Zhihao, deputy general manager of the joint venture between the Institute of PI Robotics and startup Agibot, told Yicai at the 2025 Apsara Conference on Sept. 25.

Puzhi’s bipedal robots sell for between CNY500,000 and CNY600,000 (USD70,200 and USD84,300) each, while the wheeled models are priced between CNY400,000 and CNY450,000, he said. Shanghai-based Puzhi expects shipments to rise to 1,000 units next year.

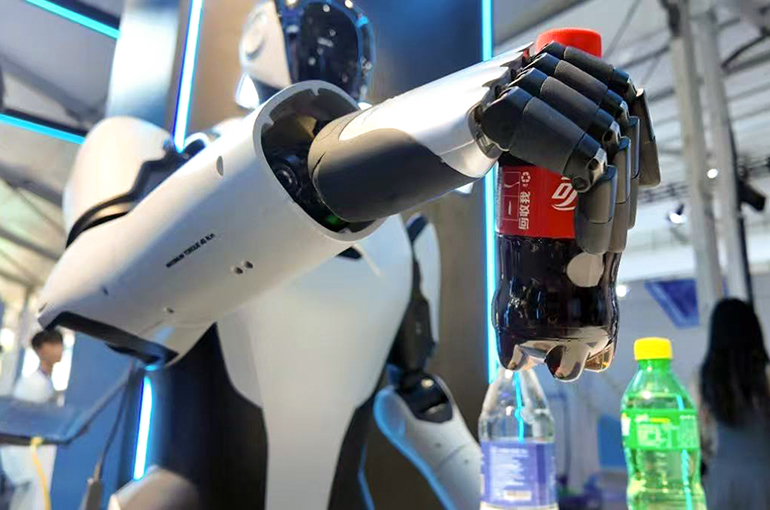

In Puzhi’s experience, developing bipedal robots is much more difficult than developing wheeled products. They need more joints, which entails more sensors. The wheeled robots are mostly used in factories, while the bipedal units are mainly used for exhibition hall tours and demonstrations, Cai said.

Fulin Precision introduced Agibot’s products into its factory in Mianyang in southwestern Sichuan province this year and after testing, the Chinese supplier of battery raw materials has since placed more orders.

Bipedal robots have the edge when it comes to uneven surfaces and climbing slopes and stairs, said Zhou Xingyou, chairman of PI Robotics. But these advantages do not matter much inside a factory.

Nevertheless, Jiang Lei, chief scientist at the National and Local Joint Humanoid Robot Innovation Center, believes that humanoid robots have a more promising future in factories than wheeled robots.

“The positioning accuracy of wheeled robots is only at the centimeter level,” Jiang said. “But industrial applications require sub-millimeter and millimeter precision. This is very hard to achieve with a wheeled base as it cannot provide a perfectly stable reference point.

“Companies are using wheeled robots to get the entire supply chain running, but once the full-body behavior model is mastered, bipedal robots will replace all the wheeled ones,” Jiang added.

Safety, technical feasibility, and economic value are still big barriers to bipedal robots working in factories, Zhou said. He estimates it may take three to five years, or even 10 years, before androids can handle full-scenario factory work. There are still many tasks in factories that cannot be automated at present and humanoid robots offer a very promising solution, Zhou said.

Editor: Kim Taylor