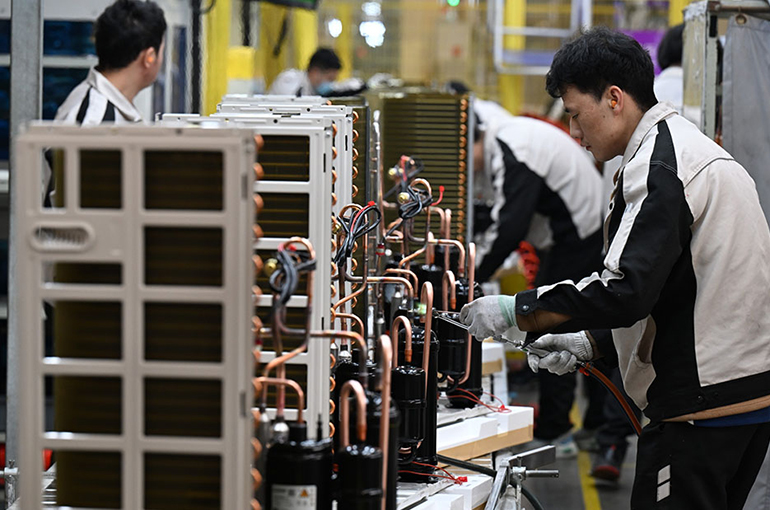

Gree Says Won’t Hike Air-Con Prices, Swap Copper for Aluminum Despite Metal’s Surging Cost

Gree Says Won’t Hike Air-Con Prices, Swap Copper for Aluminum Despite Metal’s Surging Cost(Yicai) Jan. 6 -- Gree Electric Appliances said the Chinese white goods giant will not raise its air conditioner prices and has no plans to replace copper -- which accounts for about 40 percent of the cost of an air-con -- with aluminum, despite copper’s blistering price rally.

Gree made the announcement yesterday, reiterating comments made by Chairwoman Dong Mingzhu last month that aluminum will be used in air-con units only when it can match copper’s technical performance. The Zhuhai-based company has been researching aluminum technologies for years, she said.

Copper futures have broken above USD13,000 per ton after blowing past USD10,000 at the end of last year, which prompted China’s home appliance makers to hike air-con prices. Meibo Air Conditioning revealed a 5 percent increase in December, and other big manufacturers have raised prices by 2 percent to 4 percent since the start of this year.

Air-con prices have increased by CNY80 to CNY90 (USD11.50 to USD12.90) compared with three months ago, the head of one producer told Yicai. Gree’s decision to hold may be a strategic choice, enabled by its strong brand premium and higher selling prices, which give it enough profit margin to absorb rising costs without passing them on to consumers, the person said.

“Gree’s been building a high-price, high-quality brand image, and saying that it has no plans to replace copper with aluminum right now helps to reinforce that high-end image,” said Xiao Youyuan, chairman of air-con maker Samyou Environmental Technology.

China is poor in copper and rich in aluminum, so relies mostly on imports. The industry ministry proposed replacing copper with aluminum last year, identifying the application of aluminum tubes in heat exchangers for refrigerators and air-cons as one of the key directions.

Last month, Wanbao joined hands with JD.Com to launch China’s first aluminum air-con, with presale prices of CNY999 to CNY1,199 (USD143 to USD172), about 20 percent cheaper than similar copper units on the market.

‘Reliability Issues’

“Swapping copper for aluminum does entail reliability issues, but it is not entirely unacceptable,” Xiao noted. Another industry insider said that if the switch were made and retail prices fell, some brands could see revenues plunge if they cannot grow sales, a result that would be unsustainable.

From a technical perspective, the industry has found solutions for the heat transfer performance in aluminum air-cons, making the heat exchange efficiency of aluminum alloy tubes comparable to that of copper tubes, Huang Ruiyin, a researcher at the aluminum application research institute of Aluminum Corporation of China, told Yicai.

With copper at CNY100,000 per ton and aluminum at CNY22,000 (USD3,150) per ton, and considering that the required weight of aluminum is only about 60 percent that of copper, replacing copper with aluminum can significantly save costs, Huang noted.

Japan’s Daikin Industries announced that it aims to use aluminum alloy tubes in half of its air-cons. Many window units exported to North America from China also use them.

The lifespan of copper air-cons will be up to twice as long, as modern technology optimizes performance and lifespan through alloy improvement, surface coatings, and process controls, Xiao noted. Copper’s long-term reliability advantage remains clear, and the use of aluminum would increase manufacturing costs, so companies must balance performance against cost.

The technology for using aluminum in air conditioners is relatively mature, according to the head of another air-con company. Due to market competition, although aluminum will not completely replace copper, the combination of the two will develop rapidly, they said.

Editor: Futura Costaglione