Robot Sensor Startups Haven’t Solved High Cost Issue Yet Despite Large Financing, Insiders Say

Robot Sensor Startups Haven’t Solved High Cost Issue Yet Despite Large Financing, Insiders Say(Yicai) Dec. 3 -- Startups developing sensors for robots are attracting venture capital to enhance product performance and achieve large-scale production, but they still need to resolve the crucial issue of high costs.

Daimon Robotics Technology has received a strategic investment of hundreds of millions of yuan, equal to tens of millions of US dollars, from China Mobile-backed Lianchang Fund, the visual and tactile sensor maker incubated by the Hong Kong University of Science and Technology announced yesterday. This was its second financing round within three months.

Qianjue Technology, another visual and tactile sensor startup, announced in October that it had completed a Pre-A fundraiser, its third this year, securing hundreds of millions of yuan from investors including Li Auto and GL Ventures.

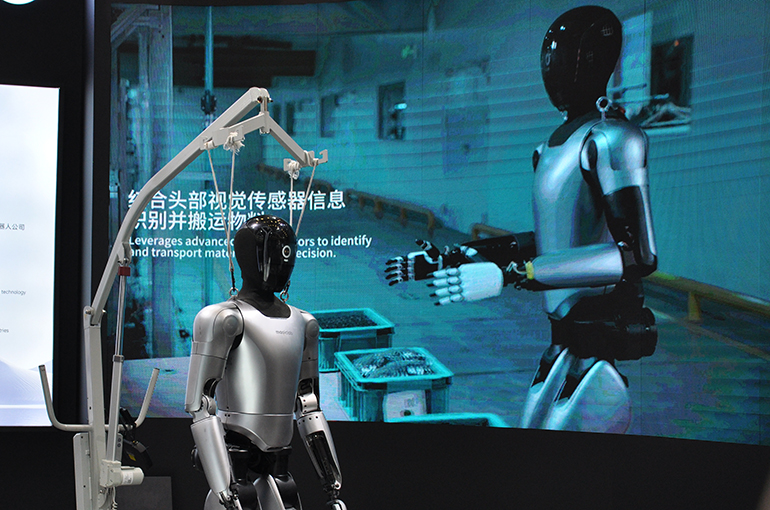

Visual and tactile sensors, such as grippers and dexterous finger pads, are mainly installed at the end of actuators to enable robots to precisely perceive the surrounding environment. They are a necessary sensing device for robots to achieve precise operations.

To apply embodied intelligence, it is first necessary to achieve physical interaction with the real world and enable robots to “obtain more accurate, detailed information to understand physical attributes, such as hardness, texture, slip, and contact sensation”, Chen Yu, an investor of Qianjue and founding partner of Befor Capital, told Yicai.

But high costs remain a common challenge for visual and tactile sensor developers. “Every company must make a trade-off between product cost, performance, and commercial scale,” a research and development engineer at a visual and tactile sensor manufacturer explained to Yicai.

Mainstream overseas visual and tactile sensing products cost around CNY7,000 (USD990) per set, while those made by Chinese peers are priced at around CNY3,000 per set, insiders told Yicai. Therefore, if dexterous hand manufacturers want to install three to five sets of visual and tactile modules on one hand, it will be costly even if they use domestic products.

After making its first-generation product, Daimon Robotics has received feedback from many clients that it is easy to use but too expensive, Du Bo, the company’s R&D director, said to Yicai. “If they deploy hundreds or even thousands of robots, their cost will be too great.”

In addition to developing new products with lower costs, increasing production scale and improving the degree of automation in the production process are also ways to reduce costs.

Yimu Technology is investing a large amount of money in deploying automated production equipment, Li Zhiqiang, founder of the Chinese visual sensor firm, told Yicai. “Before, the production of each module involved manual operation, which was not only time-consuming, but it was also difficult to ensure the consistency of product performance.”

Yimu is also considering making commercial attempts on sensor data in the future, Li said. “First, it is necessary to make sensors reliable and achieve mass production, then we can make them affordable for clients to use on a large scale. Finally, we will be able to build our own competitive edge in terms of data and algorithms.”

What truly determines the value of the visual and tactile sensors is not only the product itself, but also the combined effect of data, algorithm models, raw materials, manufacturing systems, and cost curves, according to Du.

Editors: Tang Shihua, Futura Costaglione